2000mm*14.0mm Used Slitting Machine Line

Overview Overview Basic Info. Product Description Technological Process IndroductionA slitting line is a series of machi

Send your inquiryDESCRIPTION

Basic Info

| Model NO. | 2000*14.0mm Slitting Line |

| Application | Industry |

| Type | High Frequency Weld Pipe Mill Line |

| Power Source | Electric |

| Transport Package | Wooden Package |

| Origin | China |

| HS Code | 85152191 |

Product Description

OverviewBasic Info.

| Type | Pipe Cutting Machine | Coil Width | 700-2000mm |

| Line Speed | 60~120m/Min | Sheet Thickness | 4.0~14.0mm |

| Coil Weight | Max.40 tons | Coil Material | Q235,Q345 |

| Slitting Accuracy | 0.2mm | Transport Package | Nude |

| Weight | 150 tons | Origin | China |

| Production Capacity | 10sets/Year | Machine Color | Blue and Green |

| No | Item | Numerical value |

| 1 | Coil Width | 700-2000mm |

| 2 | Sheet Thickness | 4.0~14.0mm |

| 3 | Line Speed | 60~120m/Min |

| 4 | Coil Weight | Max.40 tons |

| 5 | Coil Material | Q235,Q345 |

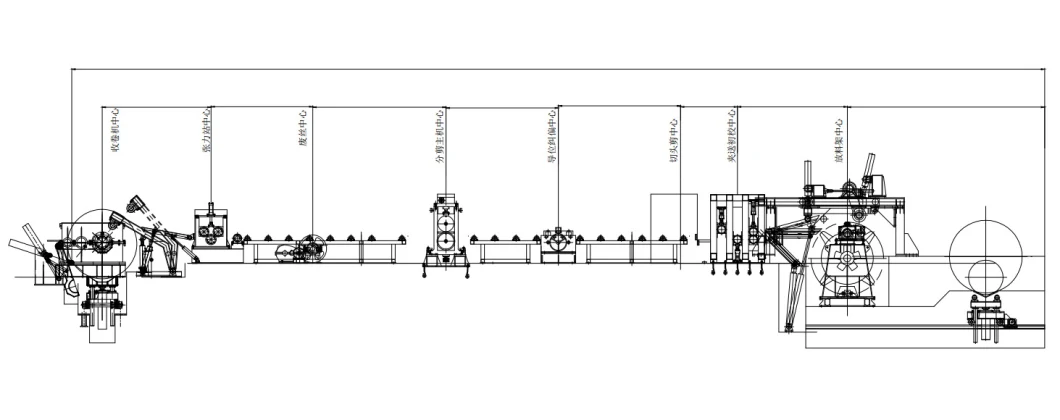

Technological Process

IndroductionA slitting line is a series of machines used to slit broad steel coils into narrower coils with specific width. The full width coil was first uncoiled and flattened into flat strip. The strip is then slit into narrower strips of narrower required width. The strips are then be recoiled into smaller coils.The equipment is controlled by PLC control system which ensures high precisely slitting and easy operation.The slitting line can be equipped with auto coil position correction which allows the uncoiler to automatically adjust its position along the signal from the coil position sensor.

Detailed Photos Product Parameters

| Coil Specification | ||

| 1 | Material | δb≤470-630Mpa δs≤345-385Mpa |

| 2 | Coil thickness | 0.3 - 2.0mm |

| 3 | Coil width | 600~1250mm |

| 4 | Coil I.D. | Φ508~Φ610mm |

| 5 | Coil O.D. | Φ1000~Φ1600mm |

| 6 | Coil weight | ≤20T |

| Line specification | ||

| 1 | Line speed | 60~120m/min |

| 2 | Power of slitter | 280KW |

| 3 | Power of recoiler | 280KW |

Foshan Shunde jinyujie mechanical and Electrical Equipment (hereinafter referred to as jinyujie mechanical and Electrical Equipment): the company was established in 2001, the main business is the acquisition and transfer of second-hand welded pipe units, and one-stop to provide customers with installation, commissioning, maintenance, customization and other services. Focusing on the high frequency welded pipe industry for 30 years, 17 years of high frequency manufacturing and service experience. In the past 17 years, we have provided more than 2000 enterprises with high quality products and one-stop service support. Second hand welded pipe production equipment and accessories, talent and technology war.A large number of second-hand real source, rapid integration of the entire second-hand welded pipe production line. Installation and commissioning services can be provided at home and abroad to ensure the rapid production of qualified steel pipes. Long term cooperation with a number of welded pipe equipment manufacturers, complete spare parts. Adhering to the development concept of "honesty, pragmatism, creating value for customers", we are committed to providing valuable services for customers.

After Sales ServiceThe sample service1.We can send you the video of the running machine.2.You are welcome to come to visit our factory,and see the machine running.Customized service1.We can design the machines according your requirements,at the same time we will give you our professional suggestion,as you know,we have been in this industry for many years.After-sales service1.We will delivery the machine and provide the bill of load on time to make sure you can get the machine quickly.2.We often ask feedback and offer help to our customer whose machine have been used in their factory for some time.3. 12 Months guarantee and life-long technical support.4.Well-trained & experienced staff are to answer all your inquiries in English and Chinese.5.24 hours for engineer response.6.Your business relationship with us will be confidential to any third party.7.Good after-sale service offered,please get back to us if you got any questions.Quality ControlOur engineer would test the machine to ensure the machine running smoothly.

Related Products

-

![Solar MPPT Charge Controller OEM ODM Power Controllers 30A 12V 24V 48V]()

Solar MPPT Charge Controller OEM ODM Power Controllers 30A 12V 24V 48V

-

![Portable Solar System 300W 500W 1kw 2kw 3kw 5kw Solar Generator System Solar Power Energy Home Solar Inverter]()

Portable Solar System 300W 500W 1kw 2kw 3kw 5kw Solar Generator System Solar Power Energy Home Solar Inverter

-

![Manufacturer Custom Nonstandard Moulded Molded Parts Other Silicone Rubber Products]()

Manufacturer Custom Nonstandard Moulded Molded Parts Other Silicone Rubber Products

-

![Fangpusun Xtm4000-48 off Grid Hybrid Power Inverter 4kVA 48V Built in Charger]()

Fangpusun Xtm4000-48 off Grid Hybrid Power Inverter 4kVA 48V Built in Charger